Our Services

Purpose Built Leak Test Machines

Our Leak Test Machines range from bench mounted high pressure leak test fixtures to fully automatic, multi-component transfer lines, including underwater leak test facilities.

Multi Component Assembly

Our range of Assembly Machines are designed for either semi or fully automatic assembly and testing or multi component parts, thus producing a quality finished product.

Process Automation & Special Purpose Machines

We have extensive experience adding value in many market sectors. From food processing to vision systems, component modifications to raw material handling. We can insert process automation and inspection into your production line.

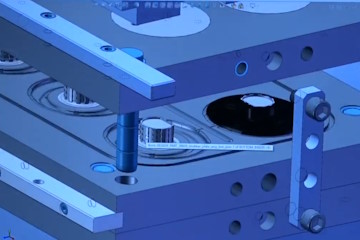

Multi Cavity Rubber Moulding Tools

We design and manufacture all of our mould tools in house. These range from single cavity rubber moulds to large rubber to metal bonded component tools, with 3D surface forms.

Mould tool repair services

From broken pillars to replacement heaters, cavity repairs or flashing. We will have your mould tool back in the press as good as new.

Sub Contract Precision Machining

From customer manufacturing drawings we provide high quality machined components and assemblies using our 5-Axis CNC machining capabilities.

Component Repairs

We can repair all kinds of mechanical components in our fully equiped machine shop. We also offer grinding, spark eroding, and wire eroding. We can inspect the accuracy using our CMM Quantum Inspection machine to 10 micron.